For sheds and garages with wooden floors

Before you get started

Prior to purchasing any shed, we recommend you check with your local government’s building/code enforcement office. Building code officials, in addition to supplying the permit, will also advise on setback requirements to determine where the shed can be placed in relation to property lines. Additionally, there may be any number of restrictions or requirements a property owner must meet, including height and/or size restrictions.

We are often asked to supply building specs, etc. As part of the permit process, and are happy to assist whenever possible.

Preparing the site

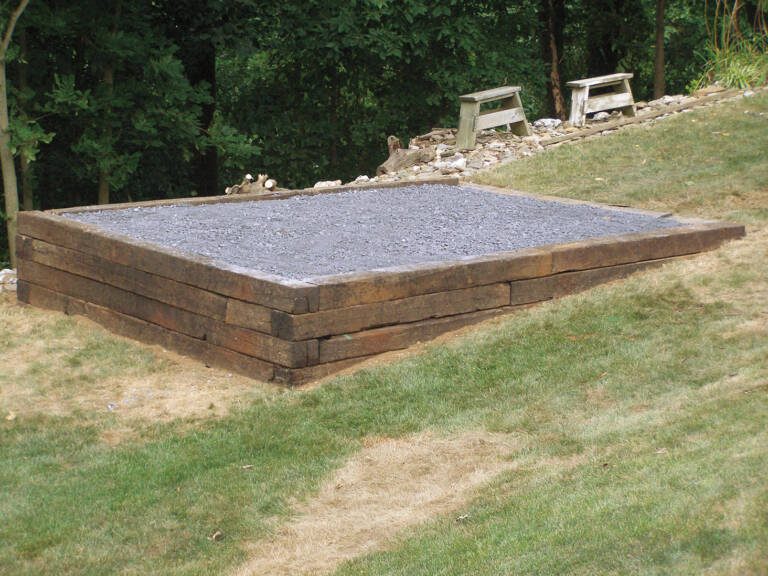

Start with a level pad of 3⁄4″ crushed stone, 3″–4″ deep, 2′ larger than the size of the shed (for example, a 10’x14′ building would require a pad at least 12’x16′). This will ensure better drainage around the perimeter of the shed — especially if you are not planning to install rain gutters. Rain and run-off from the roof will eventually create a muddy area and splash up onto the shed walls causing deterioration to the paint and wood siding. The gravel base prevents this and extends the life of the building. To prepare a gravel base, remove the sod from an area slightly larger than the pad, level the site by removing dirt where necessary, and spread the gravel to a depth of about three or four inches. Tamp the gravel until it is evenly distributed and the site is flat and level. A “frame” of pressure-treated 4x4s, or 4x6s will help keep the stone in place and create a neater appearance; however, it is not required unless you have uneven ground.

A level concrete slab that is 4″ thick on top of gravel and exactly the building size in length and width can also be used as the floor of the shed, if we are building it on site. When using concrete as the floor you must first contact us for exact dimensions. The top must be 6 inches above grade.

Not Recommended: Cinder blocks.

Inevitably, there will be some “settling” after your shed is delivered and set on its foundation. Placing a shed on cinder blocks greatly increases the risk that a shed will settle unevenly. A shed that settles unevenly will twist making doors and windows stick or difficult to open. Additionally, delivery and accurate placement of a shed is more difficult with cinder blocks as a base